The Continuous slot -wire wrapped screen is an absolutely new and effective product. It is manufactured by wrapping a wedged steel wire around loading rods which are placed according to the generatrices of a cylinder. Both steel wire and rods can be of different dimensions depending on collapse pressure and tensile stress that the screens have to bear. The wire is welded on the rods by induction.

During construction a computerized system checks and manages all the parameters in order to assure a perfect welding in every crossing point with rods.

Moreover the system controls that coils formed by wrapping the wire are always at the same distance, thus generating a continuous slot which has the same dimension in every part of the screen.

This particular construction allows to obtain a larger open area compared to other types of screen (around 50% of total area) avoiding turbulences and consequent loss of water capacity.

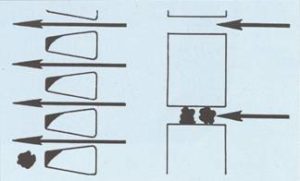

Wire shape and position (with the larger side outwards) allow the screen filter most of the grains and therefore only the smallest ones pass through slipping inside without clogging the slots (Pic. 1).